- 50+ YEARSOF EXCELLENCE

- 1,000+ CUSTOMERS WORLDWIDE

DROP WIRES

DROP WIRES

Drop Wires are a vital part of the contemporary weaving process. They detect warp yarn rupture and make it possible to solve the problem without much quality loss of the fabric.

Drop Wires go impeccably with the loom type and speed entering system, yarn characteristics and stop the motion, as and when required. The result is improved fabric quality and maximum efficiency due to minimization of false stops. Sun Brand Drop Wires comply with every application requirement for efficient operation on all types of looms.

- Suitable for all kind of auto drawing in machine

- Exceptionally well deburred process and polished

- Perfectly cut and consistent thickness across the plane

- Works smoothly with various types and kinds of yarns

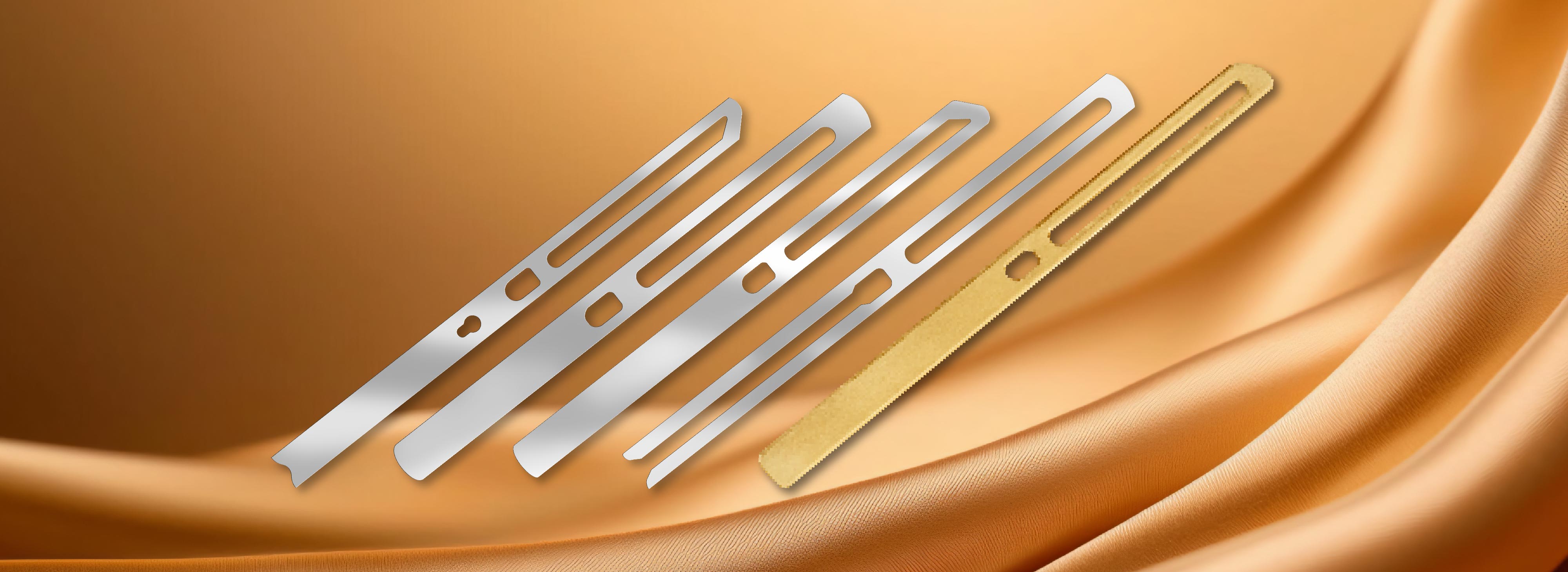

- Available in various materials including Stainless Steel, Nickle Plating and Golden Yellow Finish.

- Wide range to match today’s versatile weaving – Shirting, Suiting, Bottom, Denim, Carpet, Technical textile, to name a few.

Key features

- One of the largest manufacturing production capacities of India

- Experience of being contract supplier to European loom manufacturing companies

- State of the art manufacturing plant

- Experienced and educated technical team

Technical features

- Length : 80 mm to 268 mm

- Width : 7 mm – 15 mm

- Thickness : 0.2 mm to 1.00 mm

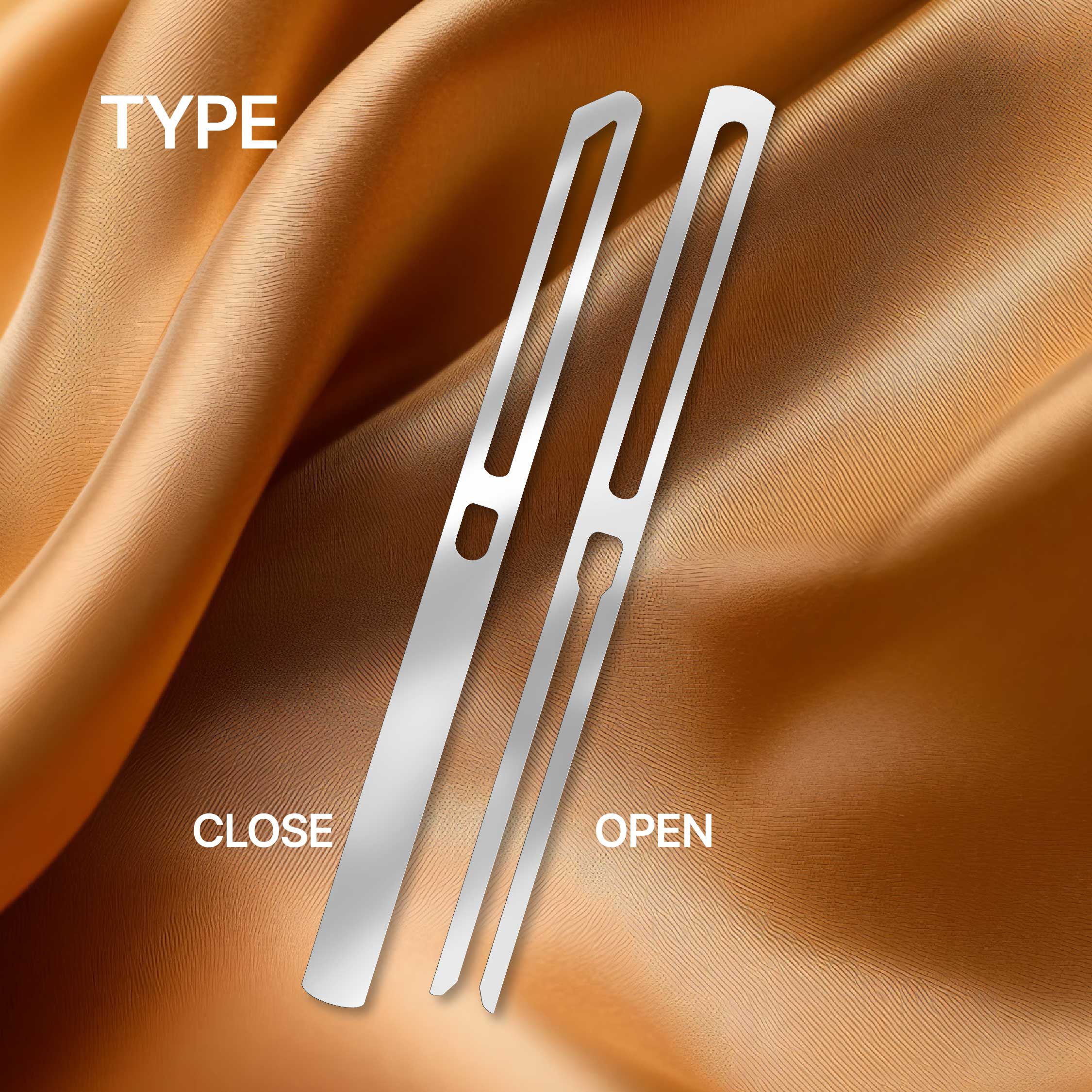

- Mechanical warp stop Motion

- Electrical warp Stop Motion

Table to determine drop wires weight as per ISO Standards.

| MECHANICAL MO = MECHANICAL OPEN MC = MECHANICAL CLOSE | ELECTRICAL EO = ELECTRICAL OPEN EC = ELECTRICAL CLOSE |

| Drop Wire Weight | Length mm | Width mm | Thickness mm | Weight gm |

|---|---|---|---|---|

| MC/EC | 125 | 11 | 0.2 | 1.7 |

| 125 | 11 | 0.3 | 2.5 | |

| 125 | 11 | 0.4 | 3.3 | |

| MO/EO | 145 | 11 | 0.2 | 1.7 |

| 145 | 11 | 0.3 | 2.5 | |

| 145 | 11 | 0.4 | 3.3 | |

| MC/EC | 145 | 11 | 0.2 | 1.9 |

| 145 | 11 | 0.3 | 2.9 | |

| 145 | 11 | 0.5 | 4.8 | |

| MO/EO | 165 | 11 | 0.2 | 1.9 |

| 165 | 11 | 0.3 | 2.9 | |

| 165 | 11 | 0.5 | 4.8 | |

| MC/EC | 165 | 11 | 0.2 | 2.2 |

| 165 | 11 | 0.3 | 3.3 | |

| 165 | 11 | 0.5 | 5.5 | |

| MO/EO | 180 | 11 | 0.2 | 2.2 |

| 180 | 11 | 0.4 | 4.4 | |

| 180 | 11 | 0.5 | 5.5 |

Determination of Drop Wire Weights

| Tex (tex) | Metr. count (Nm) | Denier (Td) | Engl. Count (NeB) | Weight (g) |

|---|---|---|---|---|

| – 9 | – 111 | – 80 | – 66 | – 1 |

| 9 – 14 | 111 – 71 | 80 – 125 | 66 – 42 | 1 – 1.5 |

| 14 – 20 | 71 – 50 | 125 – 180 | 42 – 30 | 1.5 – 2 |

| 20 – 25 | 50 – 40 | 180 – 225 | 30 – 24 | 2 – 2.5 |

| 25 – 32 | 40 – 31 | 225 – 290 | 24 – 18 | 2.5 – 3 |

| 32 – 58 | 31 – 17 | 290 – 520 | 18 – 10 | 3 – 4 |

| 58 – 96 | 17 – 10 | 520 – 860 | 10 – 6 | 4 – 6 |

| 96 – 136 | 10 – 7 | 860 – | 6 – 4 | 6 – 10 |

| 136 – 176 | 7 – 6 | – | 4 – 3 | 10 – 14 |

| 176 – | 6 – | – | – 3 | 14 – 17.5 |

Maximum Drop Wire Densities

| Thickness (s = mm) | Number per row (cm) | Number per row (inch) |

|---|---|---|

| 0.2 | 20 | 50 |

| 0.3 | 14 | 36 |

| 0.4 | 10 | 26 |

| 0.5 | 7 | 18 |

| 0.6 | 5 | 13 |

| 0.8 | 3 | 8 |

| 1.0 | 2 | 5 |

Determination of Drop Wire Weights

| Tex (tex) | Metr. count. (Nm) | Denier (Td) | Engl. Count (NeB) | Weight (g) |

|---|---|---|---|---|

| - 9 | - 111 | - 80 | - 66 | - 1 |

| 9 - 14 | 111 - 71 | 80 - 125 | 66 - 42 | 1 - 1.5 |

| 14 - 20 | 71 - 50 | 125 - 180 | 42 - 30 | 1.5 - 2 |

| 20 - 25 | 50 - 40 | 180 - 225 | 30 - 24 | 2 - 2.5 |

| 25 - 32 | 40 - 31 | 225 - 290 | 24 - 18 | 2.5 - 3 |

| 32 - 58 | 31 - 17 | 290 - 520 | 18 - 10 | 3 - 4 |

| 58 - 96 | 17 - 10 | 520 - 860 | 10 - 6 | 4 - 6 |

| 96 - 136 | 10 - 7 | 860 - | 6 - 4 | 6 - 10 |

| 136 - 176 | 7 - 6 | - | 4 - 3 | 10 - 14 |

| 176 - | 6 - | - | 3 - | 14 - 17.5 |